Easy OEE

RFID Primer

Radio Frequency Identification (RFID) is a method of identification that relies on storing and remotely retrieving data using devices called RFID tags or transponders. An RFID tag is an object that is attached to or incorporated into a product, animal, or person for the purpose of identification using radio waves. Chip-based RFID tags contain silicon chips and antennas. Passive tags require no internal power source, whereas active tags require a power source.

Radio Frequency Identification (RFID) is a method of identification that relies on storing and remotely retrieving data using devices called RFID tags or transponders. An RFID tag is an object that is attached to or incorporated into a product, animal, or person for the purpose of identification using radio waves. Chip-based RFID tags contain silicon chips and antennas. Passive tags require no internal power source, whereas active tags require a power source.

Types of RFID tags

Types of RFID tags

RFID cards are also known as "proximity" or "proxy" cards and come in three general varieties: passive, semi-passive (also known as semi-active), or active.

Passive

Passive RFID tags have no internal power supply. The minute electrical current induced in the antenna by the incoming radio frequency signal provides just enough power for the CMOS integrated circuit (IC) in the tag to power up and transmit a response. Most passive tags signal by backscattering the carrier signal from the reader. This means that the aerial (antenna) has to be designed to both collect power from the incoming signal and also to transmit the outbound backscatter signal.

The response of a passive RFID tag is not just an ID number (GUID); the tag chip can contain nonvolatile EEPROM for storing data. Lack of an onboard power supply means that the device can be quite small: commercially available products exist that can be embedded under the skin. As of 2006, the smallest such devices measured 0.15 mm × 0.15 mm, and are thinner than a sheet of paper (7.5 micrometers).[4] The lowest cost EPC RFID tags, which are standard chosen by Wal-Mart, DOD, Target, Tesco in the UK and Metro AG in Germany, are available today at a price of 5 cents each.

The addition of the antenna creates a tag that varies from the size of a postage stamp to the size of a post card. Passive tags have practical read distances ranging from about 10 cm (4 in.) (ISO 14443) up to a few meters (EPC and ISO 18000-6) depending on the chosen radio frequency and antenna design/size. Due to their simplicity in design they are also suitable for manufacture with a printing process for the antennas. Passive RFID tags do not require batteries, can be much smaller, and have an unlimited life span.

Non-silicon tags made from polymer semiconductors are currently being developed by several companies globally. Simple laboratory printed polymer tags operating at 13.56 MHz were demonstrated in 2005 by both PolyIC (Germany) and Philips (The Netherlands). If successfully commercialized, polymer tags will be roll printable, like a magazine, and much less expensive than silicon-based tags. The end game for most item level tagging over the next few decades is that RFID tags will be wholly printed - the same way a barcode is today - and be virtually free, like a barcode.

Semi-passive

Semi-passive RFID tags are very similar to passive tags except for the addition of a small battery. This battery allows the tag IC to be constantly powered, which removes the need for the aerial to be designed to collect power from the incoming signal. Aerials can therefore be optimized for the backscattering signal. Semi-passive RFID tags are thus faster in response, though less reliable and powerful than active tags. Semi-passive tags offer benefits in environments where there is a lot of metal or fluids, which typically scatter the RF field and can cause non-reads with passive tags. As semi-passive tags are pre-energized, they can be read more reliably in these more difficult environments.

Active

Unlike passive RFID tags, active RFID tags have their own internal power source which is used to power any ICs that generate the outgoing signal. Active tags are typically much more reliable (e.g. fewer errors) than passive tags due to the ability for active tags to conduct a "session" with a reader. Active tags, due to their onboard power supply, also transmit at higher power levels than passive tags, allowing them to be more effective in "RF challenged" environments like water (including humans/cattle, which are mostly water), metal (shipping containers, vehicles), or at longer distances.

Many active tags have practical ranges of hundreds of meters, and a battery life of up to 10 years. Some active RFID tags include sensors such as temperature logging which have been used in concrete maturity monitoring or to monitor the temperature of perishable goods. Other sensors that have been married with active RFID include humidity, shock/vibration, light, radiation, temperature and atmospherics like ethylene. Active tags typically have much longer range (approximately 300 feet) and larger memories than passive tags, as well as the ability to store additional information sent by the transceiver. The United States Department of Defense has successfully used active tags to reduce logistics costs and improve supply chain visibility for more than 15 years. At present, the smallest active tags are about the size of a coin and sell for a few dollars.

Bartending, RFID Style

On a busy Saturday night, a good bartender makes a lot of money for the bar's owner, but an overly generous bartender?or one fond of pouring free drinks for friends?can cost the owner even more.

On a busy Saturday night, a good bartender makes a lot of money for the bar's owner, but an overly generous bartender?or one fond of pouring free drinks for friends?can cost the owner even more.

A Miami-based 7-year-old beverage-monitoring software company is drinking from the keg of RFID and is selling a tilt switch that attaches to bottles and updates an Internet database every time the bottle is poured. Hilton, Hyatt, Outback Steakhouse, TGI Fridays and others are reportedly testing the system.

It's not merely recording how many times the bottle is poured, but it factors in the tilt of the bottle, the duration of the pour and the bartender's pouring style to calculate how much liquid is leaving the bottle.

"The software converts the tilt into an estimated volume, and the conversion is automatically perfected based on the history of each bottle; hence it becomes more accurate over time and adapts to each bartender's habits. When the bottle is empty, our sensor knows it and the software readjusts the historical pours of each bottle to the known volume of the bottle," said Beverage Metrics CEO David Teller, who said his company has between $5 million and $10 million in annual revenue. "Our system reconciles pours to ring-ups and recipes and automatically decides what is a long pour that should be changed to two pours [and] when to combine short pours in sequence."

Because the server that watches the tilt-tracking RFID system also tracks the POS (point-of-sale) system, it can also know what ingredients bartenders are using to make drinks and whether they are following the authorized recipes in addition to whether they are pouring too much or too little.

Teller said he expects the sensors to eventually sell for "less than $2 with housing, attachment means, on/off switch, tilt switch, TI micro, five-year battery and RF circuit." Right now, though, the price is closer to $5 plus a subscription fee roughly equivalent to about 1 percent of revenue, Teller said.

Teller argues that his system fits perfectly within the typical restaurant supply chain.

"We are at the cusp of changing the hospitality industry as significantly as POS did, by deploying miniature active RFID tags to every bottle received off the truck. The system reconciles the purchase order to the received goods, and the sensors ping every hour, thereby updating the inventory automatically," he said. "When a bottle arrives at a bar or banquet, the system knows where it is by the receiver location. When a bottle is tilted, the inventory is reduced by that amount and value. When the drink is rung up on the POS, it is reconciled against the pour. If there's no payment registered, the open pour is an alert. When the bottle is empty, it automatically builds the purchase order."

Although the system's readers have a range of about 50 feet, Teller said a bartender can't outsmart the system by pouring a drink beyond the range of the sensor?or simply disabling the sensor?because all of the tags are in periodic contact with the server.

"It issues an alert if the tag is removed," he said. "If the sensor doesn't ping, 'Hey, I'm here' after an hour, we start paying attention to that guy."

John Fontanella, an RFID analyst with the Aberdeen Group, dubbed Teller's system "an interesting idea" but wondered whether wireless rings around the bottles would scare off customers and chill some of the bartender-drinker relationship.

"Will it be invisible to customers? Remember those machines that were used to accurately pour a drink every time? They were all over the place, and now I never see one. There is a reason why: It ruins the intimacy created between customer and bartender," Fontanella said. "Good bartenders take care of good customers. It's as simple as that, and that's what brings them back. If the customer is unaware, or if it is in a bar with a great deal of transient traffic, it makes sense."

But Fontanella is even more cynical about whether it will truly minimize theft. "I'm already thinking about how bartenders will beat this," he said. "They will find a way."

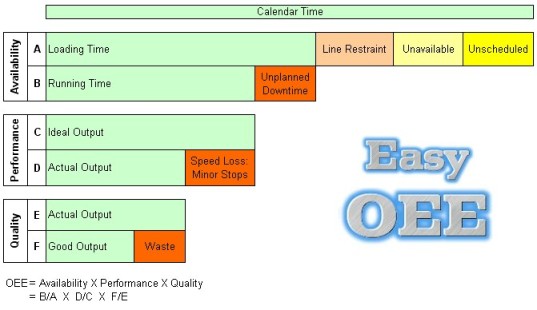

What is OEE and why should I care?

Reliable metrics have always been needed to measure the effectiveness of a process.

Overall Equipment Effectiveness (OEE) enables engineers to quantify lean improvements.

Reliable metrics have always been needed to measure the effectiveness of a process.

Overall Equipment Effectiveness (OEE) enables engineers to quantify lean improvements.

The concept of OEE has been around almost since the dawn of time. Automobile performance is measured in miles per gallon, computers measured in download speed. Even an exercise routine can be measured in completion times of the big 10 k Bellin Run. Factories measure the effectiveness of their equipment in an effort to increase optimum machine uptime and operation. All of these examples are a data driven process called OEE.

In a nutshell, OEE can measure the performance of a single piece of equipment or even an entire factory. It is governed by the cumulative impact of three factors: availability, performance and quality. Analyzing these can help to clarify a manufacturer's equipment strategy.

Often times however, OEE is underused or misapplied. When applied correctly, it can effectively increase productivity in both process and discrete manufacturing environments.

Cpk & Ppk for non-pencil pushing bean counters

In the Six Sigma quality methodology, process performance is reported to the organization as a sigma level. The higher the sigma level, the better the process is performing.

In the Six Sigma quality methodology, process performance is reported to the organization as a sigma level. The higher the sigma level, the better the process is performing.

Another way to report process capability and process performance is through the statistical measurements of Cp, Cpk, Pp, and Ppk. This article will present definitions, interpretations and calculations for Cpk and Ppk though the use of forum quotations. Thanks to everyone below that helped contributed to this excellent reference.

Definitions:

Cp = Process Capability. A simple and straightforward indicator of process capability.

Cpk = Process Capability Index. Adjustment of Cp for the effect of non-centered distribution.

Pp = Process Performance. A simple and straightforward indicator of process performance.

Ppk = Process Performance Index. Adjustment of Pp for the effect of non-centered distribution.

Kaizen philosophy and methodology

The Kaizen method of continuous incremental improvements is an originally Japanese management concept for incremental (gradual, continuous) change (improvement). K. is actually a way of life philosophy, assuming that every aspect of our life deserves to be constantly improved.

The Kaizen method of continuous incremental improvements is an originally Japanese management concept for incremental (gradual, continuous) change (improvement). K. is actually a way of life philosophy, assuming that every aspect of our life deserves to be constantly improved.

The Kaizen philosophy lies behind many Japanese management concepts such as Total Quality Control, Quality Control circles, small group activities, labor relations. Key elements of Kaizen are quality, effort, involvement of all employees, willingness to change, and communication.

Japanese companies distinguish between innovation (radical) and Kaizen (continuous). K. means literally: change (kai) to become good (zen).

The foundation of the Kaizen method consists of 5 founding elements:

1. teamwork,

2. personal discipline,

3. improved morale,

4. quality circles, and

5. suggestions for improvement.

Out of this foundation three key factors in K. arise:

- elimination of waste (muda) and inefficiency

- the Kaizen five-S framework for good housekeeping

1. Seiri - tidiness

2. Seiton - orderliness

3. Seiso - cleanliness

4. Seiketsu - standardized clean-up

5. Shitsuke - discipline

- standardization.

When to apply the Kaizen philosophy? Although it is difficult to give generic advice it is clear that it fits well in incremental change situations that require long-term change and in collective cultures. More individual cultures that are more focused on short-term success are often more conducive to concepts such as Business Process Reengineering.

When Kaizen is compared to BPR is it clear the K. philosophy is more people-oriented, more easy to implement, requires long-term discipline. BPR on the other hand is harder, technology-oriented, enables radical change but requires major change management skills.